For High-Speed CNC Machining and Hard Milling

Sophisticated NC programmers appreciate the importance of a complete, integrated CAD/CAM environment to handle the toughest manufacturing jobs. Regardless of the application, these elite users often find the need to modify, edit & create additional geometry to support the creation of toolpath.

CAM-TOOL provides Mold & Die manufactures a wide range of modeling capabilities not found in “high end” programming systems. Once your data has been prepared, the calculation of the NC toolpath is completed by simply defining your machining strategy and cutting tools. CAM-TOOL does the rest by always making sure the tool only goes where necessary to remove material using our powerful optimization capabilities.

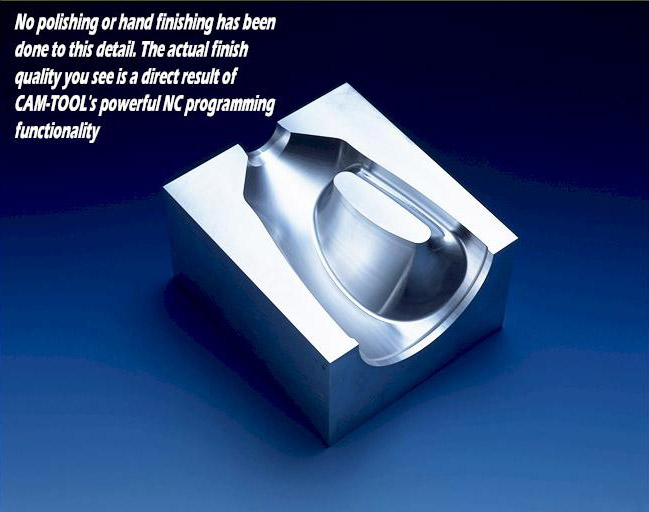

CAM-TOOL’s ability to create the toolpath based on surfaces, and not a mesh, provides unbelievable finish quality. In addition, our unique Z-Level-Offset cutting and Re-Machining strategies allow programmers of “Hard Tools” and “High Speed Machines” to control the amount of material to be removed with each pass, providing programmers with:

- Improved finish quality

- Safe unattended machining

- Increased tool life

- Reduction of benching & hand work

- Spot free and polish Free toolpath

- Operation & tool reduction

- Compatible with Windows 10, Windows 7 X64 Professional, Windows XP, XP64 and VISTA.

“Gpcam” is the Heart and Soul of CAM-TOOL with its “Tool Path directly from the Surface Calculation” using its proprietary algorithm which allows it to achieve high-precision machining.

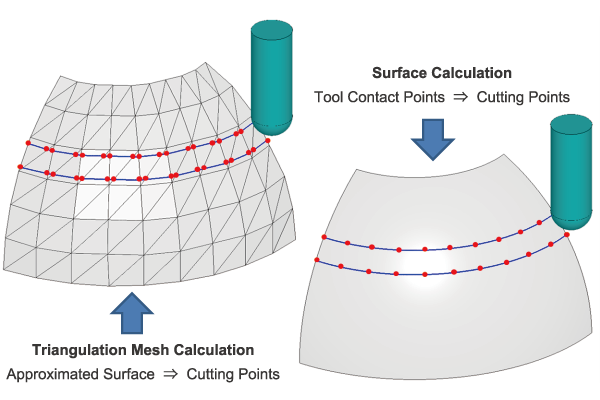

Triangulation Mesh Calculation and Surface Calculated Tool Paths

With the “Triangulation Mesh Calculation” that many CAM systems adopt, the positional accuracy is degraded since the tool-path is generated along the Triangular shapes that are approximated from surfaces of the CAD model.

With the “Surface Calculated Tool Paths” of CAM-TOOL, there is no approximation of the surface shape, so it is possible to keep the accuracy of tool-path. Since there is no gap from the CAD data, CAM-TOOL’s distinguished algorithm calculates the tool contact points on the original surfaces.

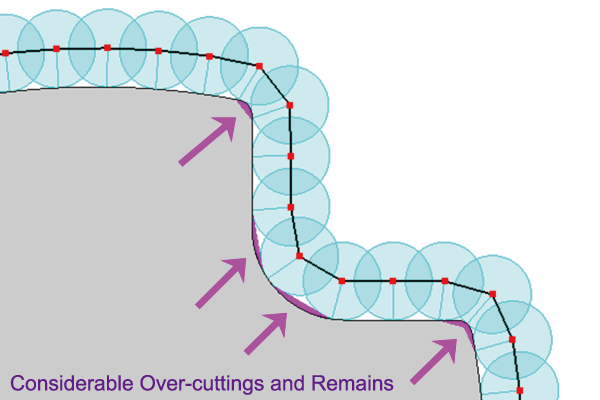

Elimination of Over-cutting (Gouging) and Leaving Remains

When machining by the tool-path with component points created using “mesh based model” (tolerance in some CAM Systems), there is the possibility of considerable over-cutting (gouging) and leaving remains (stock) in particular areas with large or discontinuous curvature, and that may cause deterioration in the accuracy of the net shape.

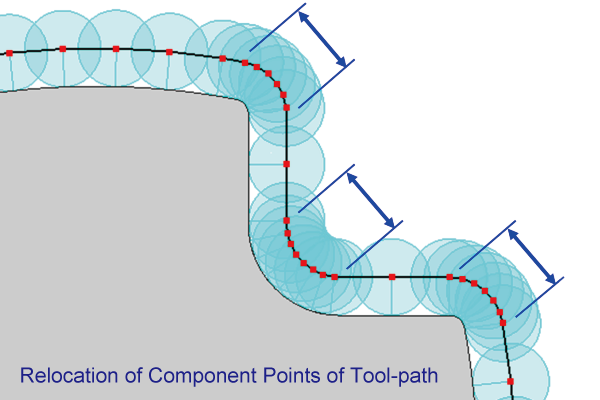

Relocation of Components Points of Tool Path

CAM-TOOL calculates relocation of component points of the tool-path using its special algorithm, corresponding to curvature of the shape. This calculation enables the proper relocation of component points along the shape. This also achieves an accurate tool-path that’s superior to other CAM Software, providing an accurate reproduction of the model shape.

SolidWorks Add-on

CAM TOOL is also available as an add-on to SolidWorks. View our SolidWorks Brochure.