Suppress tool load fluctuation with high-speed direct cutting and hard steel

The surface and polygon calculations achieve highly precise and highly efficient machining.

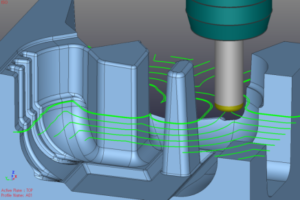

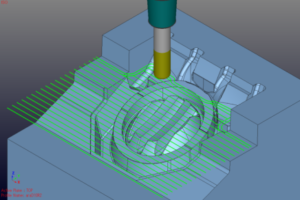

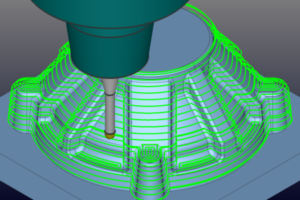

Z-level Rough Cutting with Multiple Tools

This is a rough cutting mode that performs Z-level offset cutting for a raw work material. Cutter paths are automatically created using multiple tools so that the part left un-machined in rough cutting is removed with a small diameter tool. Ball end-mill, radius end-mill and flat-end mill tools can be used in combination.

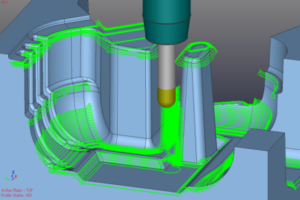

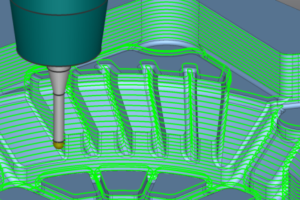

Z-level Re-machining with Multiple Tools

The remaining area is detected based on the cutter path information of the previous tool, and efficient re-machining with proper order and less retracting can be achieved.

Z-level Re-machining

This is a function that performs Z-level offset cutting for the remainders detected by specifying the tool of the previous process. Ball end-mill, radius end-mill and flat end-mill can be used.

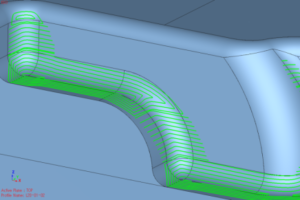

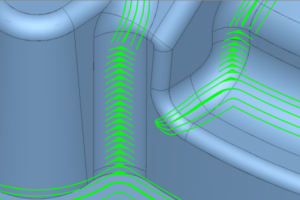

Curve Control Along Surface

This mode cuts along 3-dimensional surfaces within the closed area enclosed by contours. U/V of surfaces don’t affect the cutter paths. Air-cut can be reduced, especially for a large metal molds.

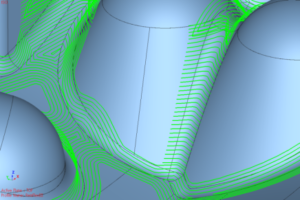

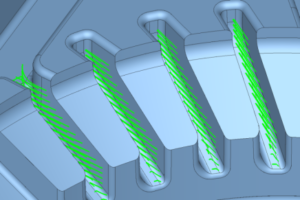

Corner Processing (Polygon)

This mode outputs “Along surface offset path” and “Contour line offset path” in the remainder regions such as groove parts or ridgeline parts where the tool of the previous process could not access. The type of the output cutter paths differs depending on the angle of inclination in the remainder region. “Along surface offset path” is output in a gently sloping area and “Contour line offset path” is output in a steeply sloping area.

Z-level Scanning-line Rough Cutting

This performs scanning-line bidirectional Z-level rough cutting. Scanning-line bidirectional cutting reduces the connecting move, which makes it possible to shorten the cutting time. Moreover, both core and cavity shapes can be cut, and for a composite shape, the system automatically detects cutting areas and outputs cutter paths.

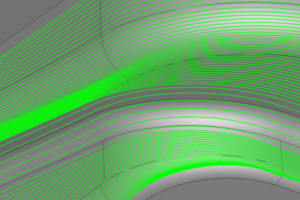

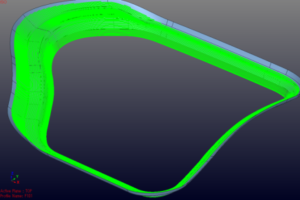

3D Offset Cutting

This is a finishing mode that outputs offset cutter paths along surfaces with a constant step. This mode outputs cutter paths for the entire shape in the specified area with a constant step and leaves uniform stock.

Z-level Finishing

Performing Z-level cutting, which uses climb cutting, suitable for high-speed and high-precision machining, provides a high-quality surface finish required for mold manufacturing. It is also possible to cut near-horizontal areas by adding “Offset cutting”, or by using “Flat part circumference” or “Scanning-Line area” together. With a variety of useful parameters and functions like “Spiral cutting”, Z-level Finishing has been widely used from the semi-finishing process to the finishing process.

Z-level Finishing (Spiral Mode)

Z-level Finishing also includes new “Spiral” cutting method. The tool path runs from top to bottom with a spiral movement without approach and escape. Since it reduces approaches and escapes dramatically, its cutter mark can be reduced. The tool path of offset cutting also runs with a spiral movement if possible.

Re-machining

This is a function for re-processing the regions that were left uncut, using a smaller tool. Based on the radius of the previous tool, remainder regions are automatically detected and cutter paths are generated for those regions only. The cutting of remainder regions can be performed along ridgelines or perpendicularly to ridgelines, depending on the angle of the ridgeline.

Cutting Range (Specify Machining Surface)

This is a method to decide the machining area by specifying a contact point between the shape and the tool. It’s possible to generate cutter paths only on the surfaces which the user wants to machine.

Cutting Mode (Surface Calculation)

- Z-level Rough Cutting

- Z-level High Efficiency Rough Cutting

- Z-level Finishing

- Z-level Scan Finishing

- Scanning-line Area

- Flat Part Circumference

- Horizontal Area Cutting

- Re-machining

- Surface Finishing

- Aiming Check

- CL + Check

- Curve Cutting

- Pencil Cutting

- Curve Control Along Surface

Cutting Mode (Polygon Calculation)

- Z-level Scanning-line Rough Cutting

- Scanning-line Cutting

- Z-level Rough Cutting with Multiple Tools

- Z-level Re-machining with Multiple Tools

- Z-level Re-machining

- Corner Processing

- 3D Offset Cutting

- Z-level Finishing