Maximizes the performance of 5-axis machining

Our Simultaneous 5-Axis Machining produces the highest quality surface finish by controlling the rotation axes smoothly with minimum change of the tilt axes. In our Simultaneous 5-Axis Machining, 3-axis cutter paths are converted into Simultaneous 5-axis cutter paths by a “5-axis conversion function”. This is a mechanism of attaching tool vector data without changing the cutter locus. This method does not require any specific skill or understanding of Simultaneous 5-Axis Machining that’s been a burden to operators, and it generates the most efficient cutter paths.

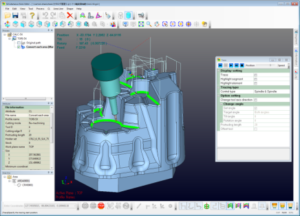

5-axis Conversion Function

Creates 5-Axis Simultaneous tool paths by adding the information about tool direction to 3-axis tool paths. In converting tool paths, “smoothing control” adjusts the tilt axis and rotation axis to make the Machine Tool move more smoothly. It is also possible to have the tool tilt gradually before the point where the tool direction changes rapidly. These functions provide the highest quality finished surfaces.

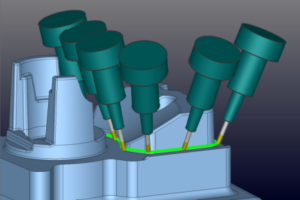

Automatic Interference Avoidance

Collision of the Tool, Chuck and Holder with the shape can be avoided by controlling the tilting axis automatically. It change the tool direction gradually to avoid a drastic change of tool direction and also minimizes the cutting mark.

Simultaneous 5-Axis Cutting Mode

- Swarf Cutting

- Z-level Undercut Finishing

- Undercut Curve Control Along Surface

- Undercut Re-machining

- Base Surface Rough Cutting

- Base Surface Side Finishing

- Base Surface Bottom Finishing