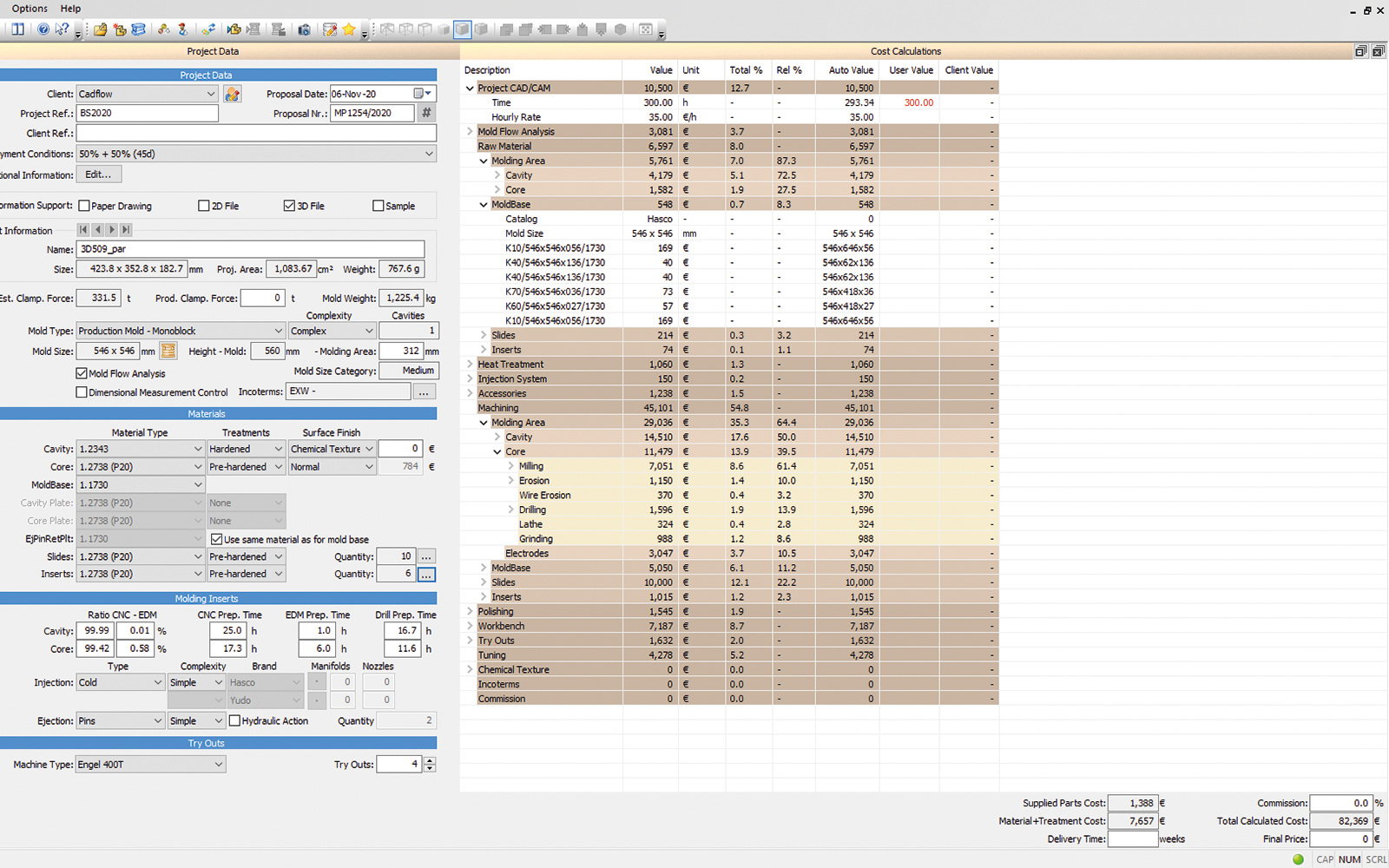

Quick and Precise Quotation of Injection Molds

QUICKQUOTE IS A SOFTWARE THAT ALLOWS YOU TO CREATE QUICK AND ACCURATE ESTIMATES FOR THE MOLDS MANUFACTURE.

Approximation Modeling

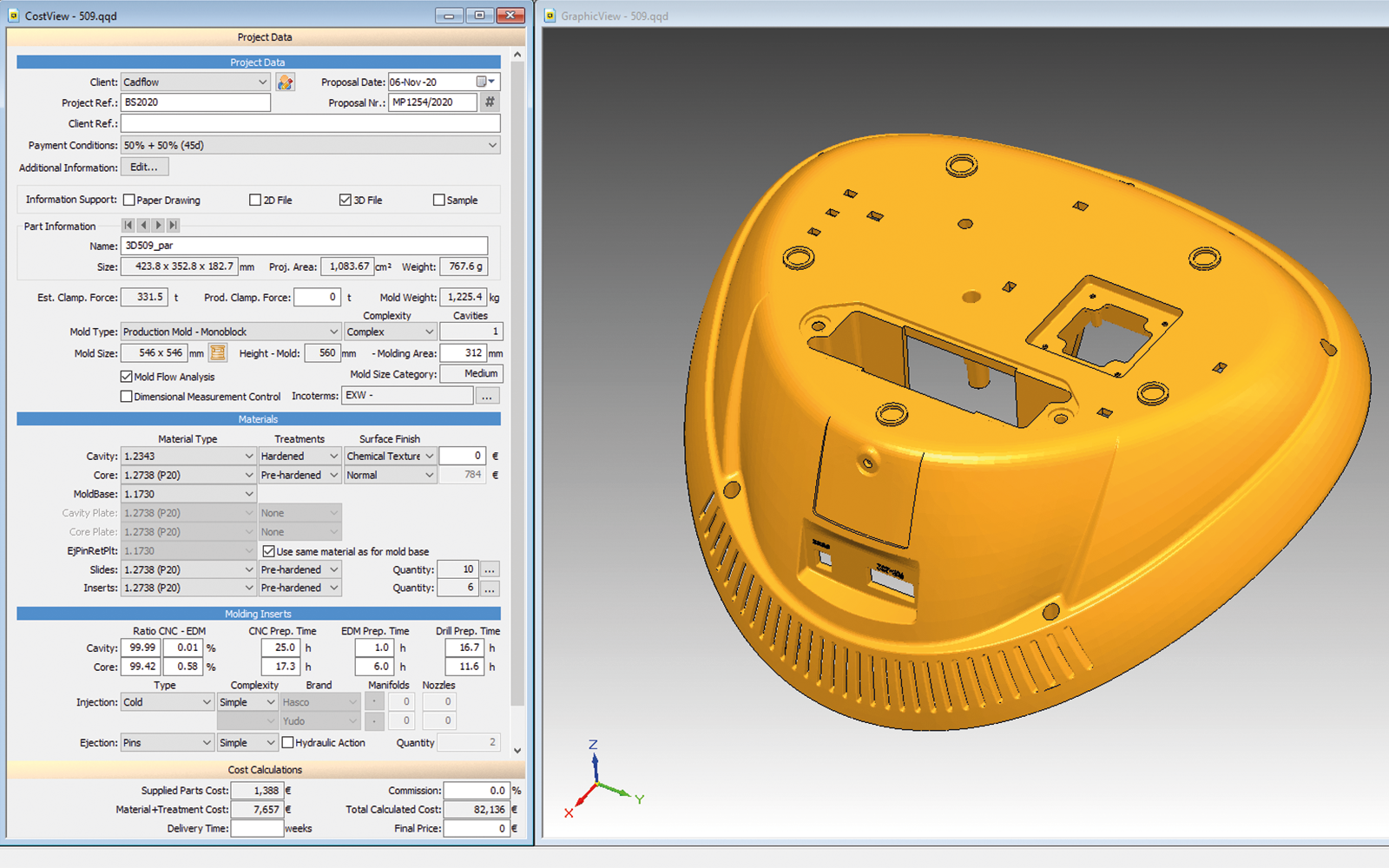

To support companies of different sizes, QUICKQUOTE is pre-installed with average costs of material and work per hour, which reflects the general reality of the mold industry. This allows you to start the quotation immediately, without complex customizations.

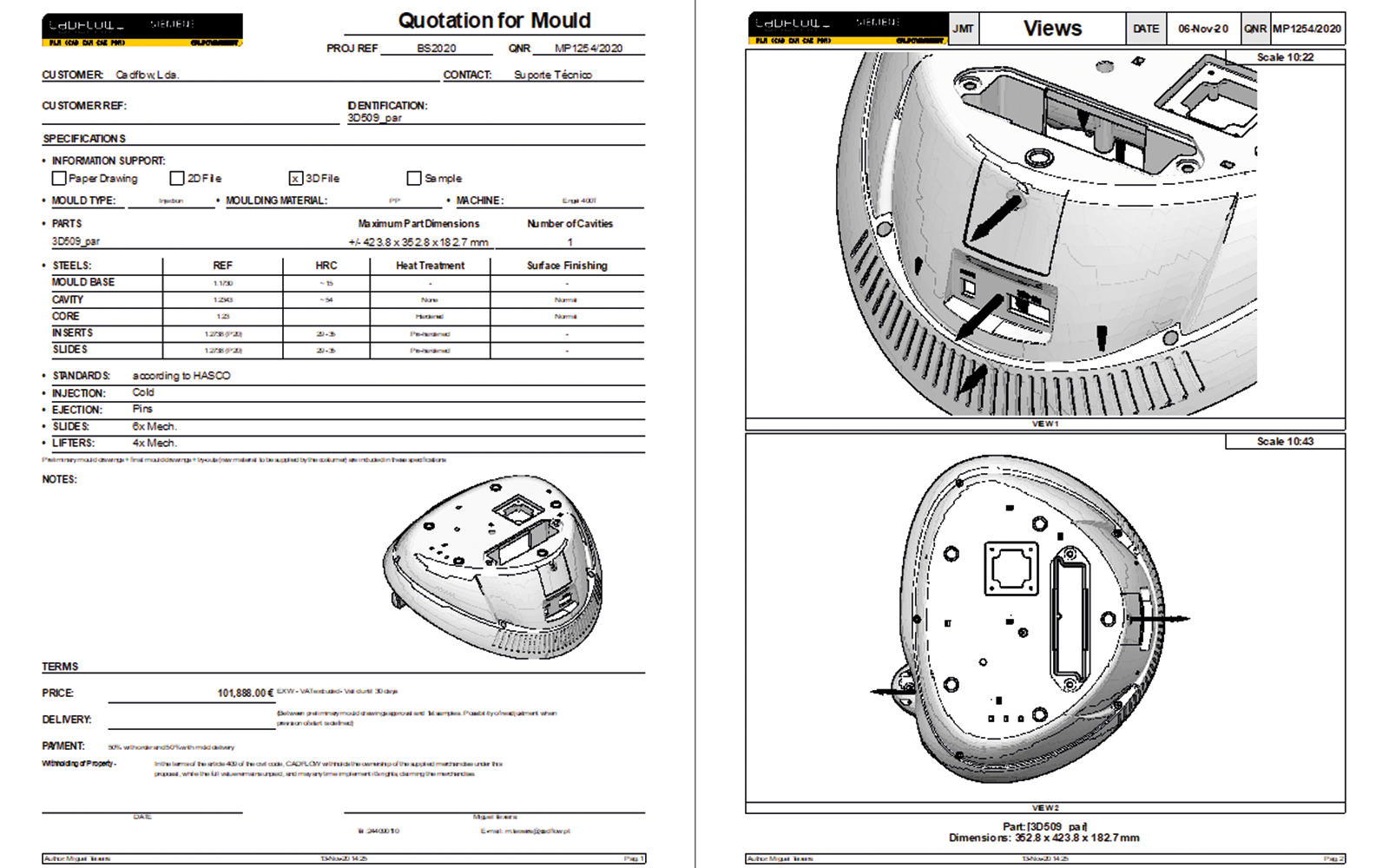

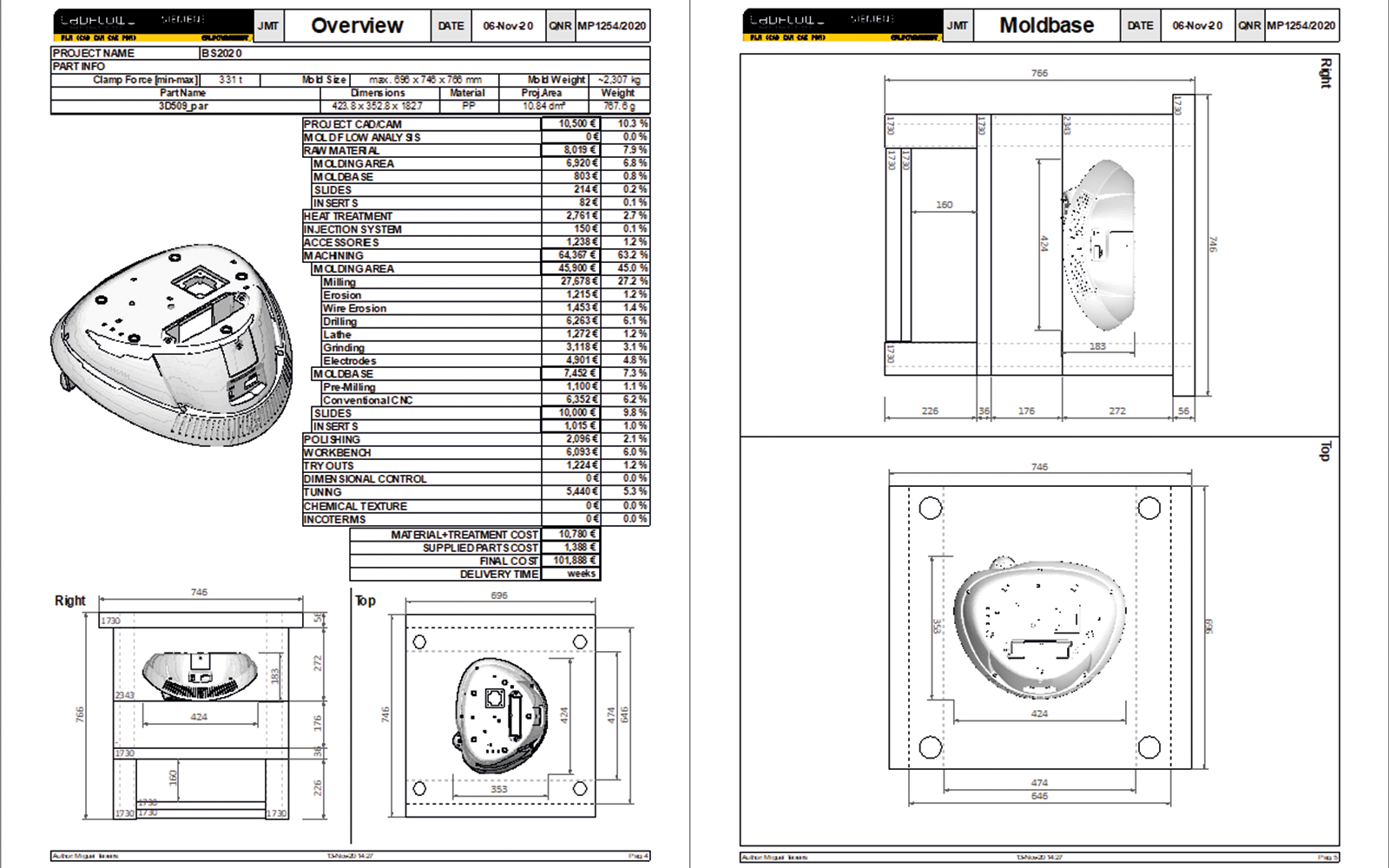

Existing forms and reports of cost estimations can be easily adapted to automate the documentation output from QUICKQUOTE with minimal effort due to the common technologies used.

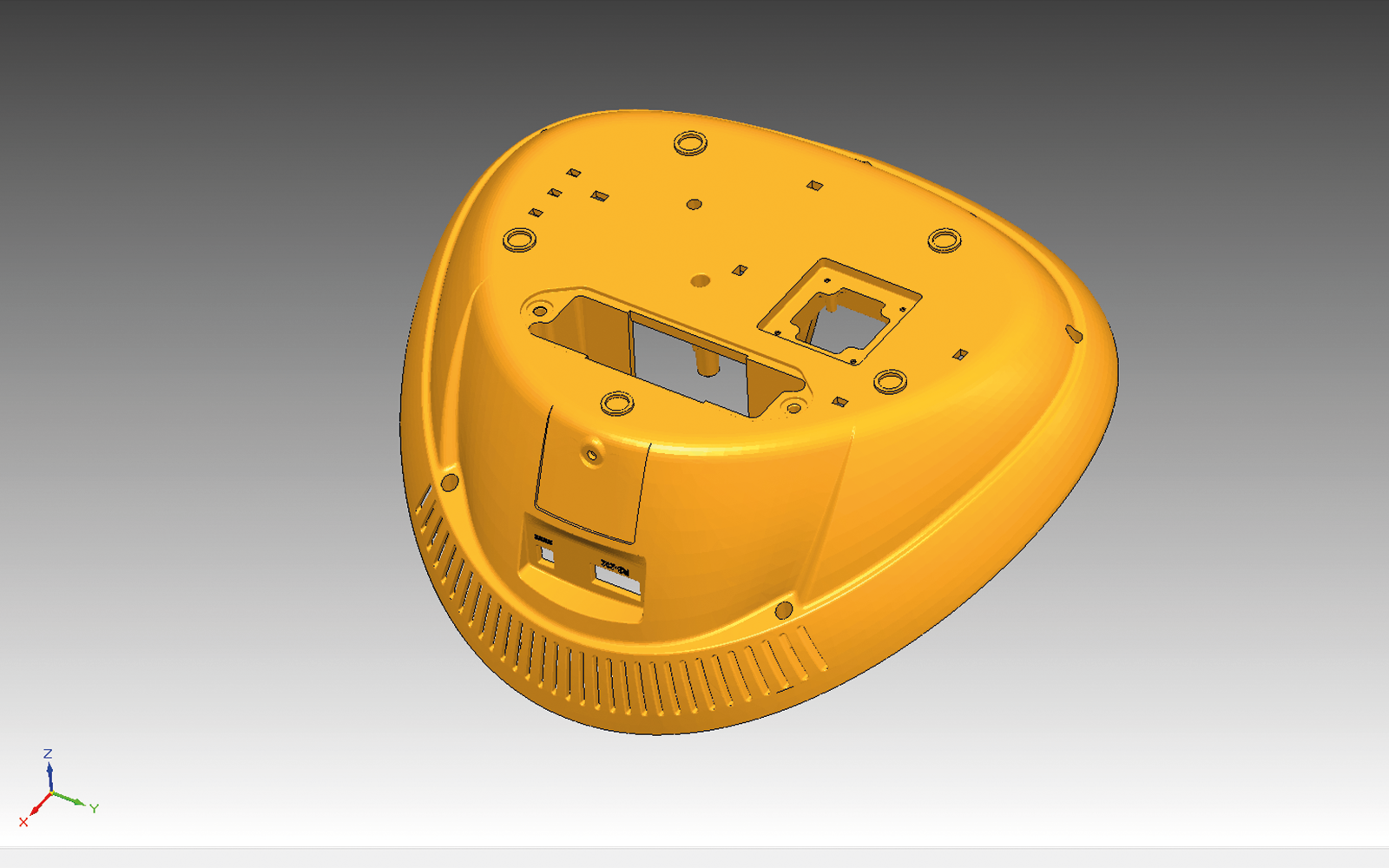

Easy Import of Geometry

To support companies of different sizes, QUICKQUOTE is pre-installed with average costs of material and work per hour, which reflects the general reality of the mold industry. This allows you to start the quotation immediately, without complex customizations.

Existing forms and reports of cost estimations can be easily adapted to automate the documentation output from QUICKQUOTE with minimal effort due to the common technologies used.

Automatic Documentation

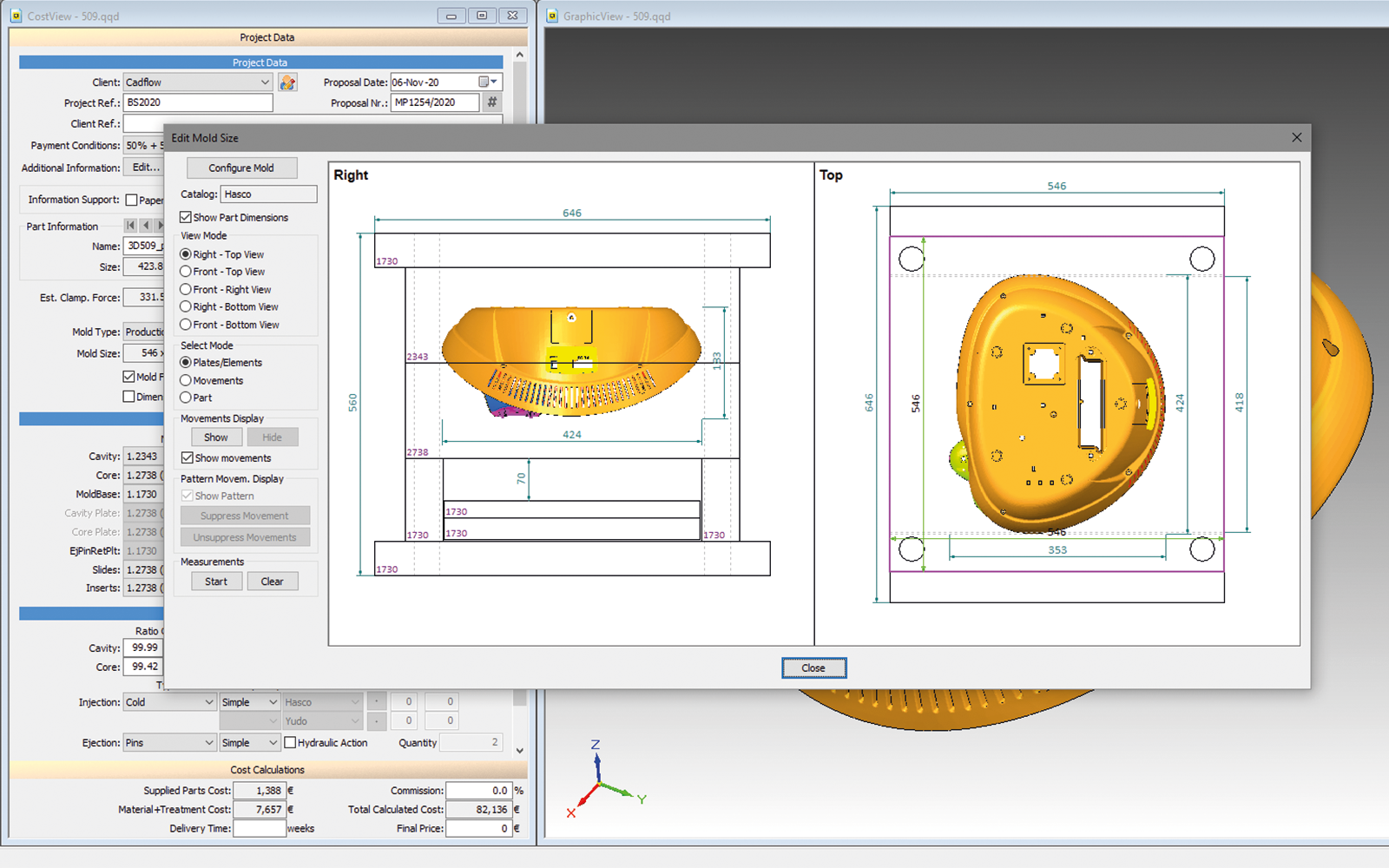

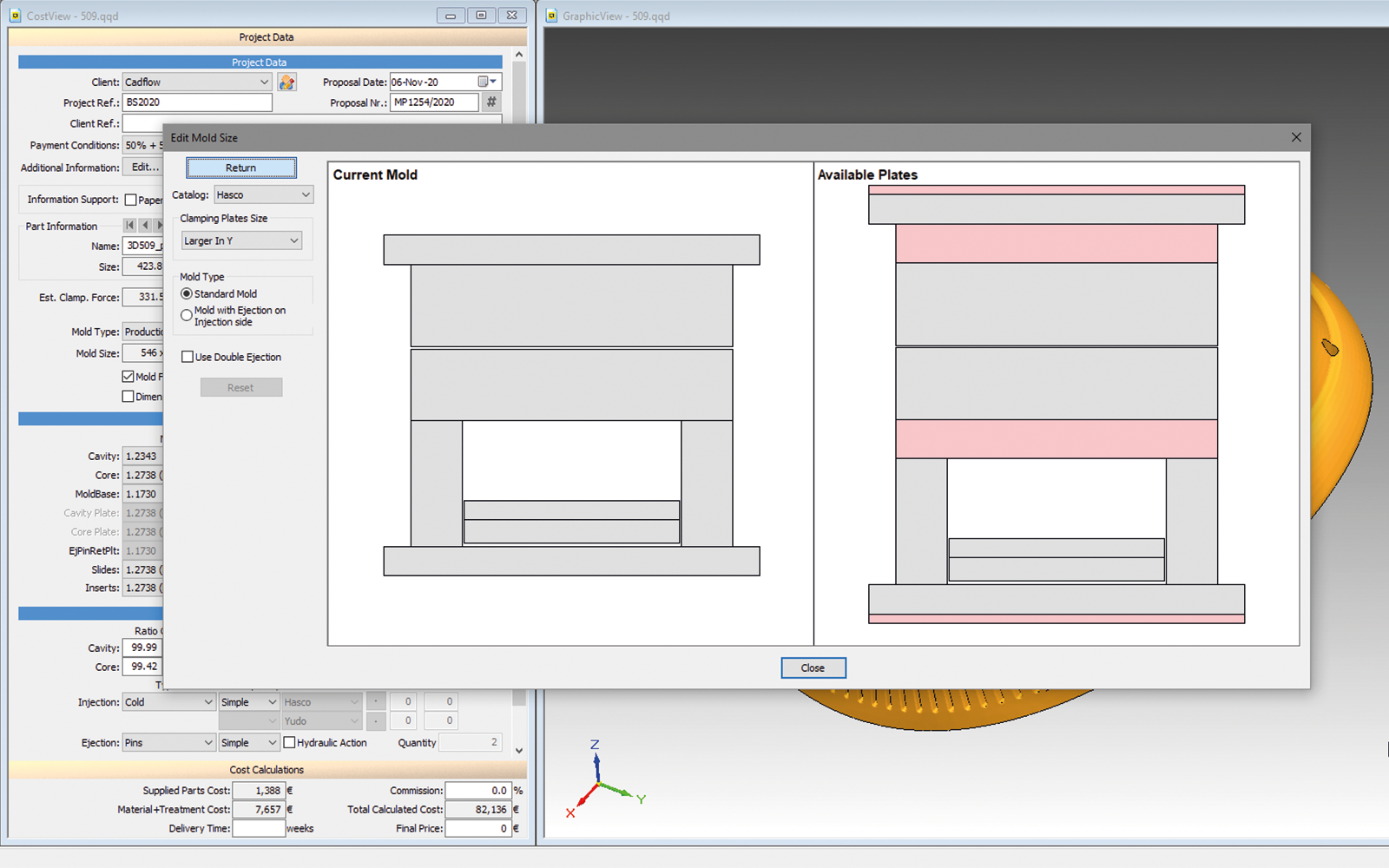

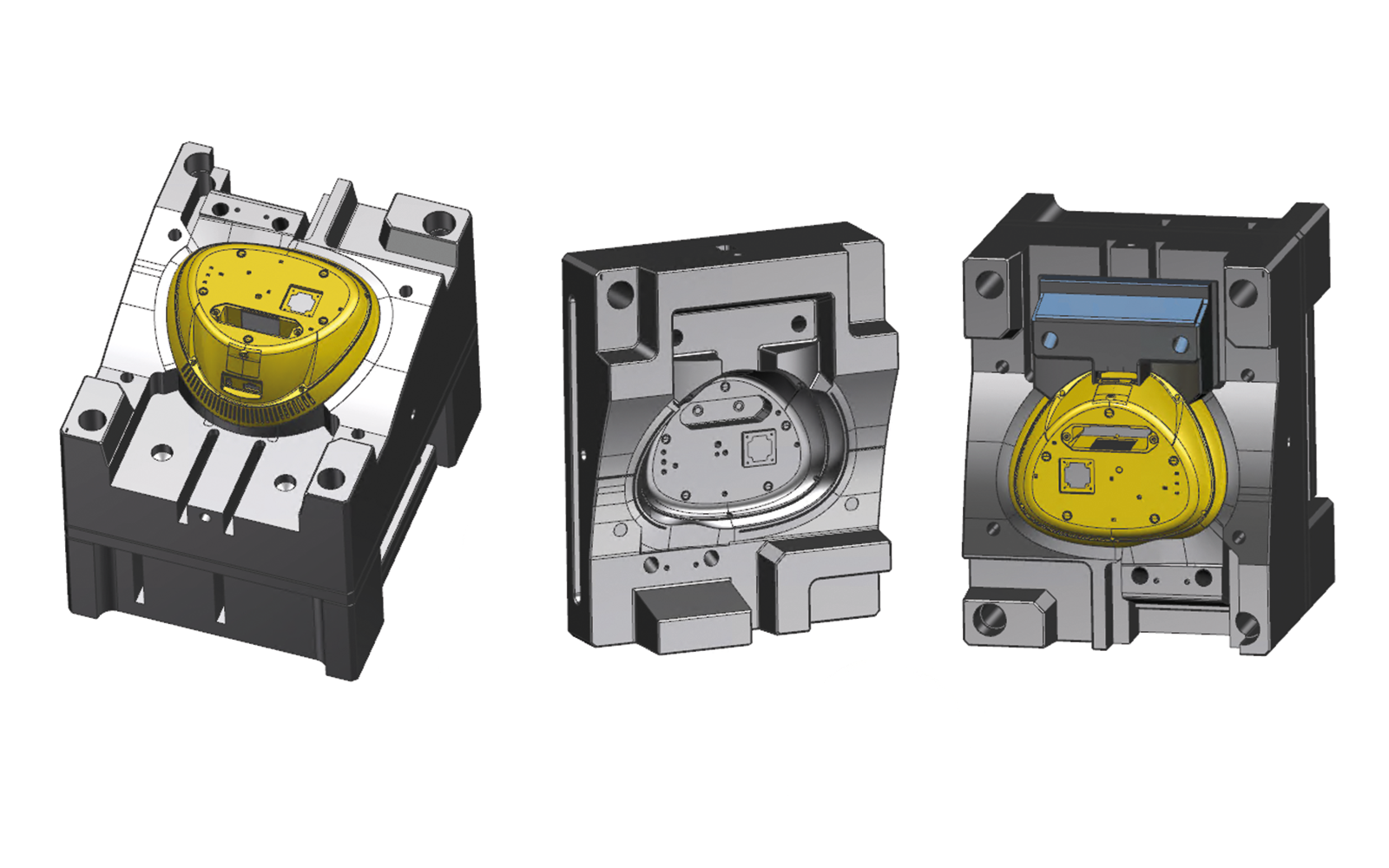

QUICKQUOTE automatically produces the preliminary drawings of the mold structure and representation schemes of slides and lifters. This allows the users to have a better perception of the work to be done and increases their level of confidence.

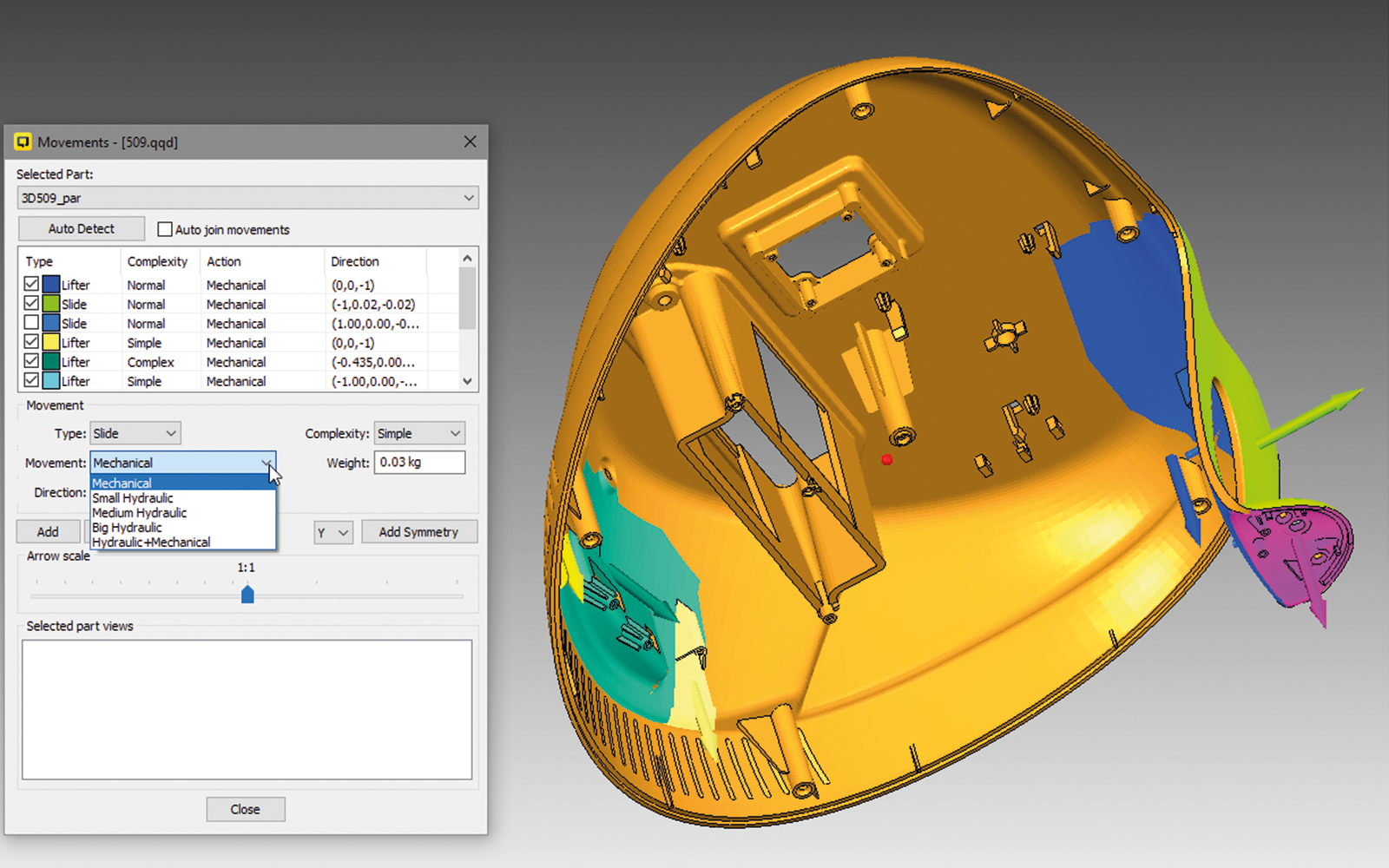

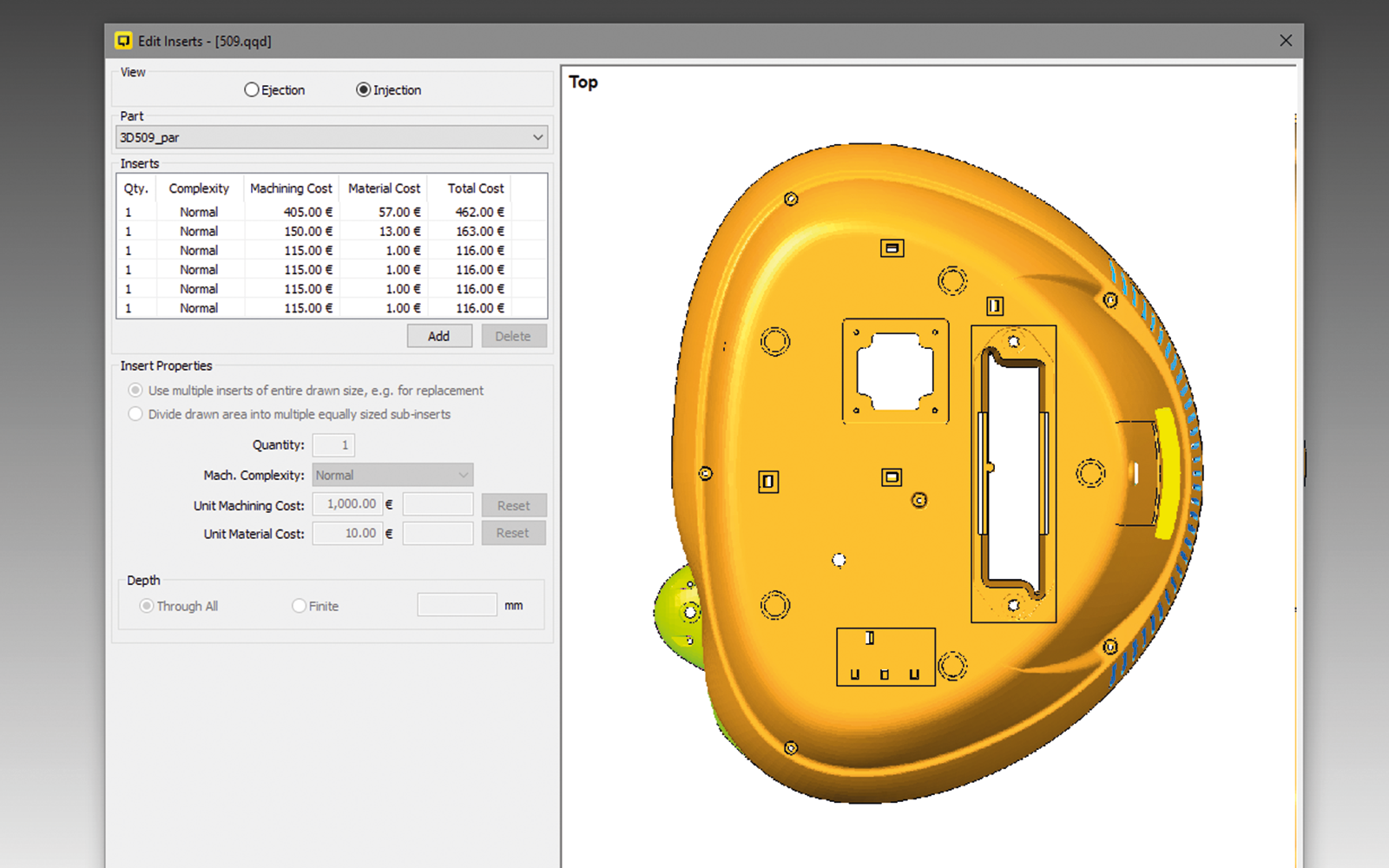

The slide components of the mold are the details that most influence the final cost and are also the most difficult mold componets to predict empirically. The current solutions on the market use extensively abstract parameters, and the user has to introduce an abstract value without knowing its impact on the final cost of the mold. This lack of transparency causes nondeterministic results and does not adequately reflect the specific industrial realities in which the project is developed.

The use of 3D models, associated with the automatic detection of sliding components and other important details of the mold while considering the geometry of the part, reflects an adequate description of the industrial reality in which the project will be developed. Based on this, QUICKQUOTE will be able to achieve repeatable and accurate results.